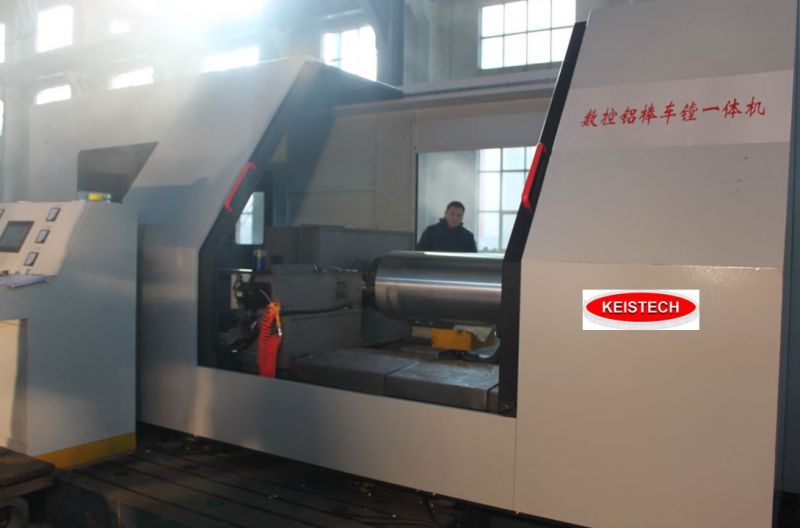

All in one lathe boring machine

National Advisory Hotline

139-0379-9695 / 189-0379-9569

Technical characteristics

1.Integration of sheet and boring:sheet and boring can be carried out at the same time,or sheet and boring can be carried out separately

2.Simplified structure,low failure rate and good rigidity:CNC manipulator is used for loading,unloading and framing,with high positioning accuracy of tube bar.The internal structure of the milling machine body is simplified,without complex spindle and positioning mechanism.Copper filings are discharged smoothly,with low failure rate and high rigidity frame structure.This structure guarantees the rigidity of the machine tool,and can meet the requirements of heavy cutting

3.NC positioning of tube and rod:the tube and rod are positioned with automatic jaws,the tube and rod are clamped from both ends of the tube and rod,and the NC manipulator is used for positioning to ensure the centering accuracy of tube and rod positioning

4.Tube rod clamping is fast and reliable:the tube rod is clamped at both ends of the tube rod with a hydraulic clamp,which acts quickly,safely and reliably,and rotates at a high speed.Each chuck is equipped with three movable tips to adapt to the turning end face of the non vertical tube rod.The chuck is quickly replaced according to different tube rod diameters and inner hole diameters

5.Fast loading and unloading:the loading system uses a dual position servo manipulator to load materials.One manipulator clamps the strip to process the tube bar for loading,and the other manipulator takes out the processed tube bar from the milling machine,lifts the tube bar away,and places it in the tube bar material frame to save auxiliary time

6.Dry cutting technology:quasi dry technology is adopted for cutting,and copper chips are dried and directly recycled

7.Cylindrical cutting lubrication process:the cylindrical chip insert is lubricated by the cutting end face of the tool to fully lubricate the tool,so as to realize the cutting cooling of the tool head,prolong the service life of the tool head,accelerate the cutting speed and improve the cutting quality

8.Boring lubrication process:boring adopts quasi dry lubrication.Boring chip cutter spray lubrication is to directly inject cooling lubricating air/liquid to the cutting head through the main shaft air hole and the spray hole of the tool base,so as to achieve the cutting cooling of the head,extend the life of the head,accelerate the cutting speed and improve the cutting quality;As a backup function,lotion lubrication can be quickly interchanged with quasi dry lubrication.

9.High pressure air blowing process for boring aluminum chips:advanced aluminum chips high pressure air blowing method is adopted for boring to discharge aluminum chips,which is easy to recover.

10.Double side cutting process:machining with precision cutter,with large turning depth and high finish:gantry frame type cutter table is equipped with cutter on both sides,and the cutting force is balanced to prevent the pipe rod from being inclined by the cutting force,improve the machining accuracy,and improve the cutting depth.The gantry frame is of solid steel structure,and the guide rail is of linear guide rail,with heavy bearing,no leakage,small friction coefficient,small transmission power,and long mechanical life,It can meet the maintenance free requirements of the machine tool guide rail,with good accuracy retention

11.Tool carrier feeding precision gear rack servo drive:tool carrier feeding adopts precision gear rack+servo motor drive mechanism,which has no vibration.The servo drive mechanism is external,which is convenient for maintenance

12.Multi blade combined cutting technology:The tool holder adopts multi blade cutting technology,and uses two cutting tools on both sides,with high efficiency and good machining accuracy

13.Bearing thin oil circulating lubrication:spray type large flow thin oil full oil lubrication to ensure bearing life and maintenance free.The lubricating oil circulates through the lubricating pump,the circulating system is equipped with a pressure detection system,and the human-machine interface alarms

14.Electrical control system:the control system adopts industrial computer+PLC+HMI control system,combined with servo system,mechanical positioning and photoelectric sensor control,so that the machine tool has high control accuracy and stable and reliable performance

15.High degree of specialization-industrialization:Case Company focuses on the design and manufacturing of turning and boring equipment,with a high degree of specialization-industrialization.The whole series includes:milling machine,boring machine,bar and tube bar grinding and polishing machine,milling chip collection device,and automatic briquetting machine,which are all independently designed and manufactured,with strong product matching and convenient service.

- Nothing

- Nothing